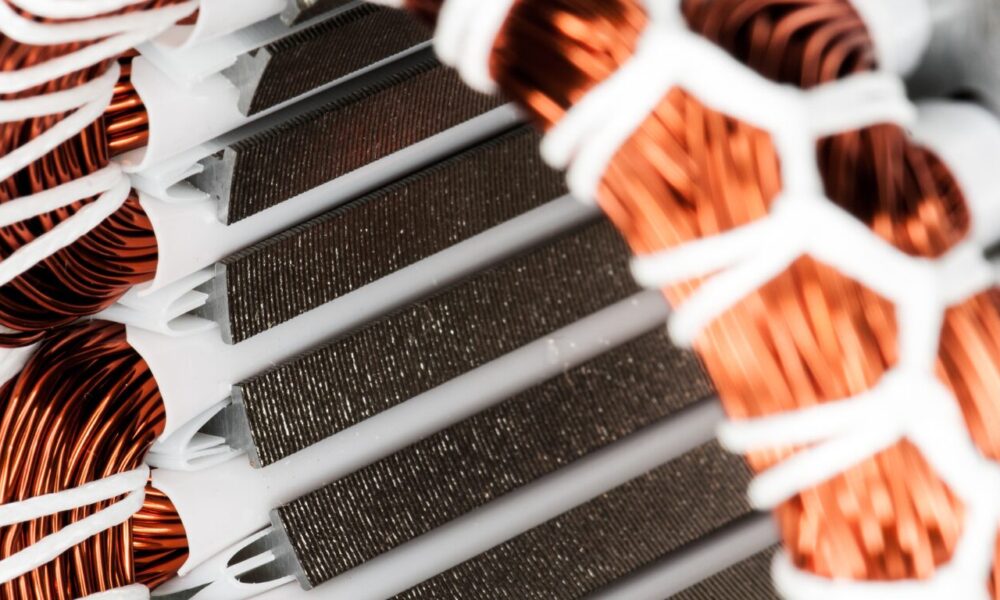

Automatic Winding Machine for Consistent Motor Coil Results

The use of an automatic winding machine has revolutionized motor coil product by icing high perfection and thickness. These machines are designed to handle the intricate task of winding motor coils with high delicacy, reducing the threat of mortal error and perfecting overall product quality. Motor winding machines are equipped with advanced features that allow manufacturers to control every aspect of the winding process, including line pressure, number of turns, and coil placement, icing uniformity across all coils. This thickness is essential for producing motors that operate efficiently and reliably.

also, electric motor winding equipment allows for lesser inflexibility in product. Manufacturers can fluently program the machine to accommodate different motor sizes and coil specifications. This capability reduces time-out and setup times, adding overall product speed. As a result, diligence that calculate on motors similar as automotive, renewable energy, and electronics — benefit from faster product rates without compromising quality. The perfection handed by these machines ensures that every motor coil meets the needed norms, perfecting both performance and continuity.

Enhancing product effectiveness with Automatic Winding Machines

One of the name features of motor winding machines is their capability to enhance product effectiveness. Traditional primer winding styles are time- consuming and bear constant supervision, leading to increased labor costs and implicit for crimes. Automatic winding machines break this problem by automating the entire process, allowing for high- speed winding with minimum intervention. This robotization not only reduces labor costs but also helps in scaling product to meet advanced demands without immolating quality.

With electric motor winding equipment, the winding process is harmonious across large product runs, icing that each motor coil is identical to the last. This thickness helps to reduce scrap material and ensures that smaller blights do. As diligence demand advanced- quality motors with better performance, the use of motor winding machines will continue to be a crucial factor in meeting these prospects. also, these machines are able of performing complex winding patterns, further expanding their versatility and making them necessary in a wide range of manufacturing processes.

Cost- Effectiveness and Precision in Motor Manufacturing

The integration of an automatic winding machine into product lines also leads to significant cost savings over time. While the original investment in motor winding machines can be advanced compared to homemade winding setups, the long- term benefits are substantial. Automated systems reduce the need for homemade labor, and the perfection of the winding process minimizes material waste. This results in lower product costs and a advanced return on investment.

likewise, the thickness offered by electric motor winding equipment leads to motors that are more effective and durable. Well- crack coils insure better motor performance, lower heat generation, and longer service life. This reduction in motor failure rates translates to smaller returns and repairs, serving manufacturers by perfecting their product’s character and client satisfaction. With further dependable motors, companies can continue to meet the growing demand for energy-effective products in colorful diligence.

Robotization for Improved Quality Control

Robotization plays a critical part in maintaining quality control in motor coil product. Motor winding machines are equipped with sophisticated monitoring systems that descry inconsistencies during the winding process. These systems insure that each coil is wound with precise parameters, which is pivotal for maintaining motor performance. The capability to cover the winding process in real time allows manufacturers to identify and correct issues before they lead to blights or waste.

In addition, electric motor winding equipment offers repetition, meaning that once the optimal parameters are set, the machine can reproduce identical coils for each batch. This thickness is vital in diligence where high- performance motors are essential, similar as in electric vehicles, robotics, and HVAC systems. By automating quality control and icing that all coils meet the needed norms, manufacturers can produce further dependable motors that perform better in demanding operations.

Unborn Trends in Automatic Winding Machines

The future of automatic winding machines looks promising, with nonstop advancements in technology enhancing their capabilities. One of the most instigative developments is the integration of artificial intelligence( AI) and machine literacy into the winding process. AI can dissect data in real time and acclimate parameters for optimal coil product, further perfecting effectiveness and perfection.

also, the objectification of advanced detectors into electric motor winding equipment will give indeed lesser control over the winding process. These detectors will cover factors similar as line pressure, coil alignment, and motor performance in real time, icing that each motor meets the loftiest norms of quality. As these technologies continue to evolve, motor winding machines will come indeed more effective and precise, paving the way for the product of coming- generation motors.

FAQs

- What’s an automatic winding machine?

An automatic winding machine is a device used to automate the process of winding coils for motors, icing high perfection and thickness in each coil produced.

- How do motor winding machines ameliorate product effectiveness?

Motor winding machines automate the winding process, reducing homemade labor, adding product speed, and icing uniformity across all coils, which leads to briskly and more effective product.

- Can electric motor winding equipment be used for different types of motors?

Yes, electric motor winding equipment is adaptable to colorful motor sizes and specifications, making it protean for different operations and diligence.

- What are the main benefits of using an automatic winding machine?

The main benefits include bettered perfection, reduced labor costs, advanced product effectiveness, and lower material waste, all of which lead to further cost-effective motor manufacturing.

Conclusion

The use of automatic winding machines in motor coil product has come a foundation of ultramodern manufacturing. These machines offer multitudinous advantages, including increased perfection, effectiveness, and cost- effectiveness. By automating the winding process, manufacturers can produce high- quality motors with harmonious results, reducing crimes and material waste while perfecting overall productivity. As the demand for energy-effective and dependable motors grows, motor winding machines will continue to play a pivotal part in meeting these requirements. The future of motor winding technology looks bright, with continued inventions set to drive further advancements in robotization, quality control, and product effectiveness.