Absolute vs. Rotary Encoders: Choosing the Best Option for Your System

Modern automation systems and motion-control systems require advanced feedback devices which operate at high precision levels. The selection process for these essential components focuses on two primary encoder types which are absolute encoders and rotary (incremental) encoders. The selection process between absolute encoders and rotary encoders requires complete understanding of their operational characteristics for building reliable and efficient systems.

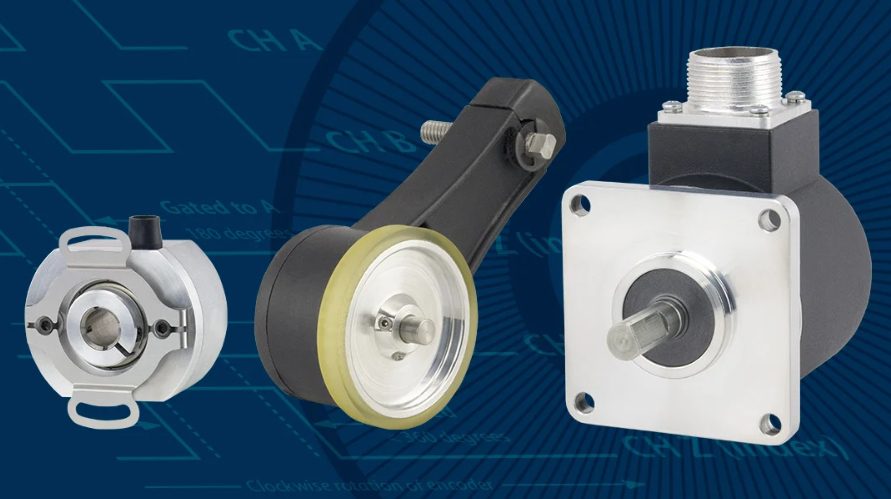

Understanding the Role of Rotary Encoders

The industrial sector along with robotics and medical devices and renewable-energy systems and numerous other applications use rotary encoders to monitor their precise position and motion. The main purpose of rotary encoders is to monitor shaft rotation while converting mechanical data into electrical output. The shaft rotation of incremental rotary encoders produces electrical pulses which directly relate to the amount of displacement or speed measurement. The system uses these encoders for applications that need to track relative movement instead of exact starting positions.

The basic design of incremental encoders allows them to detect motion through signal generation which results in fast operation and affordable production costs. The basic design of incremental encoders makes them suitable for applications that need fast feedback such as conveyor lines and motor-speed control systems. The system loses its position data when power is cut off from incremental encoders. The system needs to perform encoder re-homing after startup because it loses its reference point when power is turned off. The system operates without issues in most cases but some applications might experience extended downtime or safety risks because of this limitation.

Why Absolute Encoders Stand Out in Precision-Critical Systems

Absolute encoders maintain their position data internally which enables them to provide exact shaft positions after power interruptions without requiring re-homing procedures. The system achieves absolute position feedback through these encoders which operate independently of pulse counting methods. The system maintains its position data internally so it can determine the exact shaft position right away after power restoration without needing additional calibration.

Absolute encoders serve as the top choice for systems which need absolute position feedback because they provide dependable performance. The precise position feedback from absolute encoders makes them suitable for robotic arm systems and automated inspection tools and complex positioning systems. Multiturn absolute encoders provide complete rotation tracking in addition to precise angle measurement which makes them suitable for applications needing precise position data.

Absolute encoders maintain their position data so they simplify system startup procedures and minimize potential errors. The system can determine position without any need for motion when it operates at slow speeds or experiences brief periods of inactivity. The advanced design of absolute encoders requires higher production costs but their stable operation and decreased maintenance requirements make them worth the investment for long-term use.

The selection between absolute and rotary encoders depends on which system requirements take precedence. The selection of incremental rotary encoders proves suitable for applications that need fast speed control and relative motion tracking and do not require re-homing procedures. The combination of quick response time and simple design and wide application range makes incremental encoders suitable for numerous motion-control applications.

Absolute encoders provide superior position data reliability than incremental encoders do for applications that need precise and continuous position information. Absolute encoders eliminate the need for reference runs because they store position data which results in better machine safety and immediate position accuracy after power interruptions. The system requires absolute encoders for advanced automation and robotics applications and any other system that needs position data integrity.

The selection of appropriate encoders for modern automation systems requires careful consideration to achieve maximum operational performance. Engineers who understand the advantages and constraints of absolute and rotary encoders can pick the right encoder for their system to achieve better motion control and increased operational efficiency and extended system reliability.

Source: Absolute vs. Rotary Encoders: Choosing the Best Option for Your System